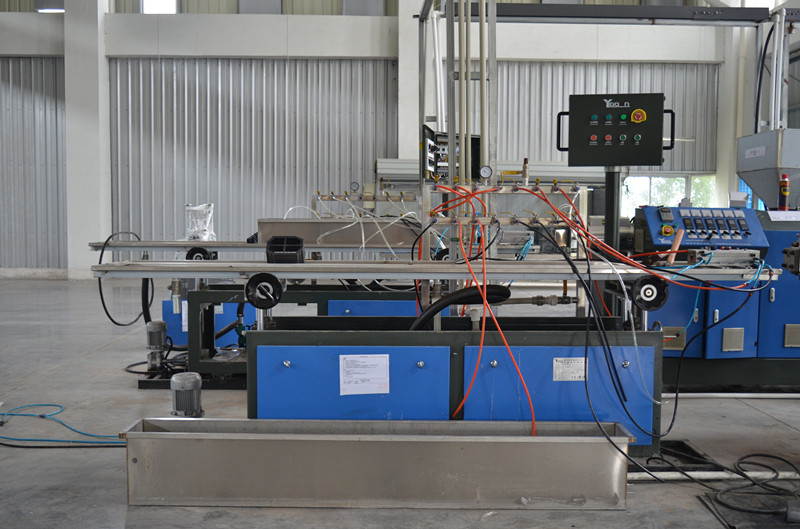

Plastic Extrusion molding

Extrusion molding

Sunmise manufacturing has been providing the highest quality cheap customized extrusion molding services for many years specializing in both large and small runs . We have our own machine shop which allows us to design and make the proper tooling for the job. This allows cost savings to the customer as well as permitting us to make any necessary adjustments to the tooling to get the final product to meet the customer’s needs. Through the years, we have produced products for major US and EU corporations as well as smaller companies. We work closely with the customer to ensure their success with their product. We work with the basic thermoplastic resins including HDPE, LDPE, Polyurethanes, ABS, Styrene, and both rigid and flexible PVC. Sunmise has the capability to do co-extrusion in which multiple extruders are feeding the material through one die to allow different colors or types of plastic on the same product.

Suitable material:

- High Density Polyethylene (HDPE)

- Polypropylene (PP)

- Polystyrene (PS)

- ABS

- Acrylic

- Polyester (PET, PETG)

- Polycarbonate (PC)

Extrusion Product Form

Circular tube, linear, semicircular, elliptic, square, triangular, porous tube, U-shaped, D-shaped, T-shaped, A-shaped, B-shaped, C-shaped, H-shaped, L-shaped, F-shaped, Z-shaped, X-shaped, plum tube, various kinds of special-shaped combined materials.

Secondary Process After Molding:

- Printing: Hot Stamping/Decal, Silk-Screen Printing, Tempo Printing, Laser Engraving, Label Application

- Assembly: Manual, Semi-Automated, Fully Automated, Clean Room

- Welding: Ultrasonic Welding, Vibration Welding, Laser Welding

- Testing: Dimensional Testing (CMM), Leak Testing, Dielectric & Electric Testing, Optical Testing

Application:

- Hardware

- Pet Products

- Window Components

- Toys

- Automotive parts

Common additives added into material:

UV inhibitors and Flame Retardants.

Packing: Carton, plastic pallet, Wooden case and so on according to customers’ requirements